Indications for the installation of porcelain crowns

The main indication for the installation of porcelain crowns is the aesthetic restoration of the front teeth:

· wedge-shaped defects and chips that cannot be eliminated using filling material;

Complete destruction of the dental crown;

· enamel hypoplasia;

Abnormalities in tooth color or shape;

· a pronounced change in the shade of tooth enamel that cannot be corrected using professional hygiene methods.

In addition, such designs are suitable for patients who are allergic to metal.

Preparation with a ledge: a necessity or a priority

With this approach, the boundaries between orthopedic dentists, therapists and surgeons are “blurred”. And it is no longer so important what specialty the doctor providing dental care is; what is important is the doctor’s choice in favor of one or another preparation technique.

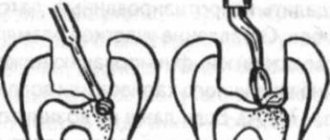

Let's first figure out what is the meaning of creating a ledge on the stump of a prepared tooth. First of all, we note that the ledge is not a supporting element for the crown, although it takes on some of the load. The need to form a ledge is dictated, first of all, by the aesthetic and functional requirements of modern orthopedic dentistry. The thing is that any artificial crown has some minimum thickness; it consists of the thickness of the frame and the thickness of the facing material. For example, the minimum thickness of a base metal frame should be 0.3-0.4 mm. Let's add here the minimum possible layer of cladding to obtain the most modest aesthetics of 0.7 mm. As a result, we get about 1 mm of crown thickness in the edge area. According to modern requirements of dentistry, we must restore the anatomical shape of the tooth without creating overhanging edges, with a smooth transition of the crown into the contours of the tooth. And this, in turn, is impossible without the formation of a ledge. Automatically, the question of the possibility of a non-invasive preparation technique can be “removed” from the agenda. You can talk about the “ledge symbol” only in the case of making a crown with a complete circular metal garland, which can be polished almost “to nothing”, but it is quite difficult to do this efficiently, and you are guaranteed a clear loss in the aesthetics of the cervical area. So is there a need for barbaric preparation without a ledge, for creating a “ledge symbol” that is barely visible to a technician, if you can simply form a high-quality ledge using modern cutting burs? The technology for creating a full-fledged ledge today is as simple as a multiplication table. And in this publication we will try to present it in the form of a certain sequence of actions by a doctor with appropriate explanations. So, step number 1. Creation of occlusal separation. (Fig. 1). We recommend performing this step with a diamond bur No. 909-xxx

rice. 1. Disconnection for the thickness of an artificial crown using a diamond bur No. 909-xxx

Step #2. Removal of large volumes of tissue from the side walls of the tooth. (Fig. 2). We recommend performing this step with an aggressive grinding bur; a TDA series bur is ideal. This stage is usually accompanied by the formation of a preliminary ledge above the gum level.

rice. 2. Removal of large volumes of tissue from the side walls of the tooth with a TDA bur. At the same time we form a preliminary ledge.

Step #3. Formation of a completed ledge at or below the level of the gums (Fig. 3). This stage must be carried out with a carbide tool. The design feature of this bur is the end end of the working head. In Great White Ultra burs, it is increased in size and has a large radius of curvature, with the constant absence of horizontal notches on the curvature of the bur head. (Fig. 4.) This design of the bur makes it simply an ideal tool for forming the final ledge on the tooth stump and finishing polishing the ledge to a glossy surface.

rice. 3. Formation of a complete ledge at or below the level of the gums.

Rice. 4. Simultaneous formation of the final ledge on the tooth stump and final polishing to a glossy surface.

According to the literature, of the many forms of ledges, the most applicable today are ledges of 135 degrees and 90 degrees (most often, its modernized analogue with a semicircular transition between the “wall and bottom” is used).

Stages of manufacturing and installation of porcelain crowns

First of all, at the appointment, the dentist examines the patient’s oral cavity, identifies possible contraindications, and, if necessary, carries out a complete sanitation. Only after this can you proceed to the next stage - preparing the tooth for a porcelain crown and selecting the optimal shade for the future design using a special template.

Next, the doctor takes a combined impression of the tooth and the entire dentition. And if the quality of the casts is satisfactory, it is sent to a dental laboratory, where a plaster model is made based on them.

Direct production of a porcelain crown can be carried out in two ways. The first involves layer-by-layer application of porcelain substance, and the second uses injection molding technology. It is the second option that is more modern and gives the structure high strength,

Therefore, it is used in most dental laboratories.

After the impression falls into the hands of a specialist, he uses thin platinum foil to create a mold for the future dental crown and fills it with a porcelain composition, and then exposes it to high temperatures several times.

The final stage of making a porcelain crown is the correction of the structure, its staining and glazing.

After the crown is ready, it is first tried on. If the result suits both the doctor and the patient, it is finally fixed on the previously prepared tooth.

Types of ledges

Before proceeding with the formation of the necessary ledge, the specialist must decide which one will be suitable in this case. There are several varieties, namely:

- a rounded ledge with a groove is the most commonly used option. Most specialists use this option for creating a ledge before installing a metal-ceramic structure. The width of such a ledge ranges from 0.7 to 1.3 mm, which will subsequently preserve the hard tissues of the tooth - enamel and dentin;

- A ledge made in the form of a knife is a good option when installing solid crowns, as well as teeth that have slopes. The width of such a ledge is narrower than rounded. It ranges from 0.4 to 0.5 mm;

- the shoulder type of ledge is the least effective, but the most aesthetic type. It reaches 2 mm in width.

Types of ledges

Various forms of cervical ledges in the manufacture of artificial crowns

Video - Tooth preparation for a crown

Benefits of porcelain crowns

· High aesthetics. Porcelain has almost ideal optical characteristics. It very accurately conveys the natural shade and translucency that are characteristic of natural tooth enamel.

· Hypoallergenic design and inert material. Porcelain does not have thermal conductivity, so tooth sensitivity to temperature changes is reduced. Since the crown does not contain a single gram of metal, it can be installed in patients who are allergic to it.

· Long service life. With proper care, the structure will last a very long time, approximately 10-15 years, without losing its performance characteristics.

· Resistant to staining and darkening. Porcelain crowns do not lose their shade and shine, maintaining their original appearance for a long time.

· Minimum adaptation time. The patient quickly gets used to the lightweight and comfortable design.

· Easy to care for. Crowns do not require special care. It is enough to use a high-quality toothbrush and toothpaste, and treat them with care.

Disadvantages of porcelain crowns

· High cost of construction. It is due to the complexity of technical work, which requires very high professionalism from a specialist.

· Relative fragility of the material. Patients have to avoid eating solid foods.

· Restrictions on indications. Porcelain crowns are not placed on all teeth.

· Manufacturing of single crowns only. Porcelain is not suitable for creating and installing bridges.

Making a temporary crown.

For some reason, some doctors ignore this stage, leaving the choice to make a temporary crown or not to the patient. In fact, a temporary crown must be made without fail. Especially if a living tooth is being treated for a crown. It protects the gums from injury during eating, prevents neighboring teeth from moving, and in the case of a living tooth, protects the tooth from infection by oral microflora and from various irritants - temperature, chemical, etc. There are a lot of ways to make “temporary items”, so we will not dwell on this in detail. It is important that the temporary crown obtained by any of the methods sits exactly on the ledge, is well polished along the edge, and excess temporary cement is carefully removed.

The plastic temporary crown is installed exactly on the ledge (in this case, the truth is slightly different in shade from its neighbor)... After removing the temporary crown, the gums are absolutely healthy, there is no bleeding...

Varieties of porcelain designs

Dental porcelain is an excellent material that provides ample opportunities for aesthetic restoration. Several types of structures are made from it:

· Veneers. These are thin plates designed to hide minor defects in tooth enamel. They cover only the front surface of the tooth. Porcelain, composite or zirconium dioxide can be used in their manufacturing process.

· Tabs. These are microprostheses made in a dental laboratory. They help solve more serious dental problems with teeth and are used, for example, in cases of severe decay of the crown or the presence of a large carious cavity.

· Crowns. The most versatile design that allows you to achieve a “Hollywood” smile. They are installed on the front teeth during aesthetic restoration.

The need to create a ledge

Specialists do not always make a ledge when grinding a tooth before placing metal-ceramic crowns. There are several reasons for this:

- The turning time, which is done without a special ledge, is reduced several times.

- When creating the necessary ledge, you need to have a specialized set of materials and tools, as well as experience working with them.

- In order to prepare a tooth and create the desired ledge, it is necessary to have a specialized thread that is laid in the space between the gums and teeth. This technique is necessary in order to protect the gums when working with special attachments and creating the necessary ledge. To place this thread you need a specialized tool.

- Availability of expensive material from which the impression will be made.

- A mass is needed from which the so-called “shoulder” will be formed in the future.

The relationship between the edge of the ceramic crown and the gingival ledge of the abutment tooth in relation to the mucous membrane

It is worth noting that a tooth prepared without a ledge can become infected, and the tooth itself can be destroyed. This can cause inflammation of the gums and many complications in the future.

- Ceramic crowns

Below are popular methods for grinding teeth for metal-ceramic crowns.

| Methodology | pros | Minuses |

| Turning using ultrasonic equipment | Hard tooth tissues cannot be heated. Painless. No pressure is created. There are no minor damages. | |

| Laser turning | It works almost silently. The speed of the procedure is at a high level. There is no chance of infection of the patient's dental tissue. Fabrics do not heat up. There are no chips or cracks in the tooth. This procedure is absolutely safe. | |

| Tunnel preparation method | The advantage of this technique is the control over the removal of tooth tissue. | Pulp injury due to improper grinding technique. The risk of overheating of the tooth, as well as the presence of pain if the anesthetic does not work as necessary. Presence of chips and cracks in case of tool failure. |

| Tooth preparation using the air-abrasive method | No special skills required. The grinding speed is quite high. There is no feeling of discomfort and pain, as well as overheating of tissues. Vibration is eliminated. Preservation of most of the tooth enamel. | If the mixture gets on the hard tissues of the tooth, it begins to destroy them. |

| Method using chemicals | Eliminates the effect of overheating. There is no need for preliminary anesthesia. Violation of the structure is excluded. The procedure is absolutely silent. | The mixture takes a long time to leave the mouth. |

It often happens that after installing metal-ceramic crowns, the patient experiences discomfort and pain in the area of the new prosthesis. The reasons for this may be:

- violation of the procedure for grinding mineralized tissue.

- inflammation of the apical part of the tooth and processes of inflammatory etiology in the soft tissues of the tooth.

Grinding teeth for crowns

In all possible pathological conditions, it is necessary to contact a specialist as soon as possible to correct these errors. Otherwise, complications may develop.

Metal ceramics or porcelain: what to choose?

This question arises among patients quite often. After all, each design has its own advantages and disadvantages. Thus, metal ceramics are distinguished by their high strength and affordable price, and porcelain has excellent aesthetic characteristics. Typically, the choice between them depends on which tooth needs to be restored. Crowns made of metal-ceramics are most often installed on chewing teeth, and porcelain crowns are installed on incisors and canines. However, if a porcelain crown has a zirconia framework, it can be used to restore any tooth.