1706

The choice towards one or another model of dental implants is always determined by the ratio of price-quality criteria. Traditionally, leading positions are occupied by systems from the USA, Korea, Germany and Israel.

For some time now, orthopedic dentists have begun to offer Russian analogues for tooth restoration, which in most characteristics are not inferior to foreign ones.

Dental implant companies and manufacturing countries

Today, there are a number of manufacturing countries that occupy a prominent place on the implantology map. Dental implant companies located in these countries produce about 90% of the total number of implants on the market. If you go to the website of any dentistry, then in the “implantation” section you will probably see countries such as the USA, Switzerland, Germany, Israel and Korea. Most ordinary people do not know how this or that implant differs, but at the same time, any sane person realizes that a two- or three-fold difference in price should imply at least some differences. That is why the question: “Which brand of dental implants is better?” – asks most patients. It is difficult to answer this unequivocally, because each clinical case may have its own recommendations and limitations. Below is a rating of dental implants by manufacturers from different countries, which will help you understand the variety of systems, their advantages and disadvantages.

Our doctors

surgeon-implantologist Dimitrovich Denis Alexandrovich

The implantation procedure using the Rusimplant system is performed by an implant surgeon, dentist

orthopedic dentist Lyabov Roman Anatolievich

The procedure for prosthetics using the Rusimplant system is performed by an orthopedic dentist

Certificates

Certificate of conformity of the Niko system

Certificate of conformity of the Niko GOST R system

Registration certificate

Questions and answers on this topic: Dental implantation, Dental prosthetics

You can make an appointment at Apex-D Dentistry by calling the administrator at +7 and +7, or filling out an electronic form (the administrator will contact you at the specified phone number and agree on the date and time of the appointment).

Swiss dental implants

Switzerland is often associated with the production of cheese and watches, but implantation can also be added here. It is this country that produces the highest quality, most expensive and well-known brands of implants. We are talking, first of all, about Nobel Biocare and Straumann. They have the highest survival rate (99% and above) and the best technology. It is Swiss implants that allow you to obtain ideal aesthetic and functional results even in the most difficult cases. The majority of clinicians in the world prefer to work with Swiss manufacturers, many of whom are real luminaries of implantology. By the way, to use the capabilities of these systems 100%, you need to be really high-level specialists. Now about the less pleasant moments. The cost of implants from Switzerland is the highest on the market. On average, for the installation of Nobel Biocare or Straumann implants alone, you will have to pay 45–50 thousand rubles. Add to this cost the cost of prosthetics, and you will get a sum close to 100 thousand.

Swiss dental implants Nobel Biocare

Reviews

A large number of reviews from patients confirm the opinion of experts that inexpensive implants can be of decent quality. Russian designs from the companies Konmet, Iris and Rusimplant have precisely this feature.

You can share your thoughts regarding the feasibility and justification of using domestic artificial roots when restoring teeth by leaving a comment on this article.

If you find an error, please select a piece of text and press Ctrl+Enter.

Tags implants implant manufacturers

Did you like the article? stay tuned

Previous article

What to do when braces rub your cheeks or advice from experts

Next article

Characteristics of the best materials for dental implants

American dental implants

The most popular American dental implants are Bicon, Biohorizon, as well as implants from the Denstply concern. If the first two systems can be considered local developments, then Dentsply is a slightly different story. A huge holding company, which has been selling dental equipment since its founding (and this is 1899), at some point wanted to enter the implantology industry. The company did not start from scratch and invest huge amounts of money in developing its own technologies, but simply gradually acquired several good European manufacturers with all the staff and developments. We are talking about Ankylos (Germany), Xive (Germany) and Astra Tech (Sweden). The most successful was the purchase of Astra Tech, which was in the top 3 and occupied about 30% of the implantology market. Despite the merger with Dentsply, all acquired companies retained their brand and continue to produce implants under it.

Americans are excellent businessmen who have taken marketing and PR in dentistry to a whole new level. At the same time, American dental implants also mean quality, high survival rate and reliability. On average, you will have to pay 30–35 thousand rubles for American-made implants (BioHorizons, Ankylos, Xive), and the elite Astra Tech will cost 40–45 thousand.

Bicon line of American dental implants

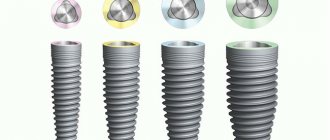

Model overview

Analog products from some Russian companies can be a good alternative to popular implants.

Having applied global experience in their work, domestic manufacturers produce no less high-quality, and most importantly, more affordable dental structures.

Conmet

The company's catalog is presented in three models:

- Classic. These are screw artificial roots with double thread. They are produced in two diameters – 4.8 mm and 4.0 mm. Lengths 8.0 mm, 10.0 mm and 12.0 mm.

They are equipped with a platform switching function, due to which the rod is inserted with minimal resorption of the jaw bone and maximum aesthetics.Double thread ensures uniform distribution of the chewing load, and high-tech surface treatment ensures accelerated osseointegration. The systems are recommended for use in two-stage classical surgery.

- Cylindrical. Having a cylindrical shape, they are produced in diameters of 5.5 mm and 3.5 mm with individual selection of lengths (from 8.0 mm to 16.0 mm).

Aggressive threads help securely secure the product in bones of different densities, so they are used when the height of the alveolar is insufficient (up to 10 mm) or when performing one-stage implantation. - Conical. Depending on the location of the dental unit being restored, the rods are produced with diameters of 4.5 mm or 3.4 mm.

They can be implanted into the socket of an extracted tooth, if it is close to the area of the maxillary sinuses and neurovascular bundles to be restored, or if the volume and quality of the jaw bone is insufficient.The tapered shape of the shaft combined with the aggressive threading provides sufficient initial stability and further stability.

In addition to the indicated indications for use, Conmet systems can be installed for any form of edentia, end or frontal defects of the dentition, the impossibility of removable prosthetics, or for fixing conditionally removable or bridge dentures on implants.

As features of dental structures from this manufacturer, it is worth highlighting the following:

- Only hypoallergenic high-quality materials are used for production. Artificial roots are made of purified titanium, their periosteal part is coated with aluminum oxide, and the intraosseous part is coated with titanium powder, which guarantees rapid integration of the product.

- It is possible to implant some models immediately after tooth extraction , due to which the level of bone loss is reduced significantly.

- High quality implantation is ensured by the use of high-tech equipment and new materials . In the process of creating dental systems, precision laser cutting of parts, plasma coating, anodized titanium, and finishing are used.

- Strengthening the neck of artificial roots ensures uniform distribution of the chewing load along the entire length of the product, which reduces the likelihood of its fracture.

- It is possible to make an implant from a gold alloy (at the patient’s request). But here you need to realize that gold, in comparison with titanium, has high ductility, which negatively affects the ability to withstand high loads.

Among the advantages provided by the use of Konmet models, the following points are indicated:

- A wide range allows you to choose an option that suits a specific clinical case.

- The use of three-dimensional prototyping technology during production, which makes it possible to manufacture individual implants, reduces the duration of osseointegration, increases the accuracy of fixation and reduces the traumatic nature of the process.

- Affordable price. The manufacturer's policy made it possible to set a price for products that is several times lower than foreign analogues.

- High aesthetics , thanks to which it is possible to restore even the frontal group of teeth.

- Versatility , which means the system can be implanted using various protocols.

Among the shortcomings, one can highlight such factors as isolated cases of rejection, which are mainly due to the actions of the patient himself, or the doctor’s violation of the installation protocol due to unprofessionalism.

The video provides additional information about Konmet implants.

Rusimplant

The catalog presented by the company contains several options for dental implants intended for use in a specific clinical case.

Leader

The models are suitable for solving various clinical problems. This became possible thanks to the use of special manufacturing techniques.

The design is distinguished by the presence of a dodecahedron, a self-sealing fit cone, and two types of self-tapping threads - large aggressive and small six-start.

The conical shape of the screw ensures atraumatic and, most importantly, rapid insertion into the bone.

Pros: sufficient primary stability, the ability to be implanted into weakened bone tissue, resistance to lateral loads, and the ability to compact bone mass.

Short

This is a shortened model with a wide diameter, which can be installed without prior bone grafting surgery.

Models are recommended if there are problems with the condition of bone tissue or reduced alveolar height. A product with a three-start self-tapping thread with an angled shoulder.

Rods can be implanted when there is insufficient bone volume , installation is quick, and osseointegration time is reduced.

Assets

The model is intended for use in cases of severely weakened jaw bone. Features: presence of a landing cone, hexagon, hollow design, apex with 2 through holes on the sides.

The neck has fine carvings, which gradually give way to large ones. The thread is equipped with a self-tapping function.

The shape of the artificial root is designed so that the bone is practically not damaged during its insertion , and the presence of a cavity and a pair of holes improve tissue nutrition under the surface of the structure.

Positive aspects are the rapid process of osseointegration, the absence of bone injury and support for its nutrition.

Lux

The rods are installed in bone of any density. Fine threads are applied to the upper part in increments of 0.25 mm, and large threads (0.75 mm) are applied to the lower part.

This thread geometry ensures painless insertion of the implant and obtains primary stability.

Pros: long service life, increased contact area, good stability.

Standard

Available with a semicircular apex and aggressive trapezoidal thread with a pitch of 0.8 mm. Advantages: no vertical shift of tissues under high loads, large contact area.

Today, Standard implants have been discontinued by the company.

Mini

They are used to place temporary prosthetic structures during long and complex restoration of dentition.

Also application cases are:

- immediate restoration of facial aesthetics;

- protection of soft tissues in the area where the permanent structure is implanted;

- insufficient alveolar height.

It is produced in two versions - with a cone-shaped head for securing a fixed prosthesis, and with a spherical head for removable structures.

Advantages: sufficient primary stability, simple installation.

Three popular models of Ards implants and indications for their use.

Come here to take a closer look at the design of 3i biomet implants.

At this address https://www.vash-dentist.ru/implantatsiya/proizvoditeli/roott.html read how the issue of installing Roott implants is resolved.

Small

Implants of this series have a small diameter and are intended only for the restoration of the upper (lower) incisors.

The systems show good stability in cases of bone deficiency and low alveoli, thanks to the presence of fine threads in the cervical region and larger threads on the body.

Fixation of the prostheses occurs due to the presence of an internal hex screw. It also minimizes the likelihood of the artificial root breaking due to overload. Pros: good primary stability, accelerated osseointegration, stability.

Features of systems from the Rusimplant company are the following characteristics:

- Material . All produced models are made of purified grade 4 titanium, characterized by ideal biocompatibility, bioinertness, increased strength, hypoallergenicity, and durability.

- Surface . The presence of the Smart surface allows for accelerated osseointegration.

- Geometry. Each version produced has a cylindrical hexagonal shape, but differs in thread, apex shape and abutment type.

- Versatility. Thanks to many modifications of artificial roots, doctors can restore teeth in any clinical cases.

- Sterility. Each structure is irradiated with gamma rays, which guarantees complete disinfection of their surfaces. Upon completion of processing, the implants are placed in a sealed package that maintains sterility. All packages are supplied with a quality certificate.

- Life time. The company guarantees a 15-year service life for all models. If you follow the recommendations for care and use, the actual service life increases to 25 years.

The undeniable advantages of the systems are:

- cost, which is half lower than foreign analogues;

- good survival rate;

- sufficient strength;

- ease of installation;

- the presence of a modern technological surface;

- compliance with all international quality criteria;

- practicality.

The main disadvantage is that they cannot provide the same aesthetic indicators in the frontal zone as their foreign counterparts.

Iris

The company produces four models for its potential patients:

- LIKO-M .

Classic model with atraumatic apical end and frequent thread stroke. Suitable for recreating large chewing elements. It has protection against self-twisting, high strength, and accelerated osseointegration. The design prevents the entry and proliferation of pathogenic bacteria under the prosthesis and provides an expanded area of contact with the bone body. - LIKO-M EVOLUTION. Intended for implantation in areas with low quality and sparse bone tissue during surgery with one-stage prosthetics.

The implants have a standard length, a rare but high thread, which ensures the best fixation in the bone and rapid integration. - LIKO-M SLIM. Non-standard model - has a diameter of only 3.0 mm.

Installation is recommended for poor-quality bone or its small volume and width. Also suitable for replacing lateral incisors in any jaw. Despite its small size, the product shows sufficient stability and strength. - LIKO-M MINI. It is a cone-shaped product with a rare thread pitch.

It is produced in two versions of the supragingival part - spherical and square. The systems are designed to secure any type of prosthesis. But more often they are used as a basis for a conditionally removable system.

Iris products gained popularity and demand thanks to:

- A shortened rehabilitation period, occurring in most cases without complications.

- Good biocompatibility, which is achieved by using titanium purified from additives.

- Satisfactory survival rate , achieved due to the presence of a rough microrelief on the surface and repeated etching of the material with acid.

- Reducing the occurrence of long-term complications to zero, thanks to the barely visible gap between the abutment and the intraosseous part.

- Quality . Despite the fact that the system in question is a Russian development, its production takes place in Italy. Each stage is controlled and carried out using Swiss and Italian equipment.

- Wide range of applications . The versatility of the models allows them to be used in different clinical cases, and at the same time achieve high quality indicators of the operation.

- Possibility of replacing individual components. With long-term use of the structure, the abutment can be replaced for further prosthetics.

Important! Relative disadvantage is overpriced. When analyzing prices for middle-class implants, the models considered cannot be called cheap.

Zimmer trabecular implants and their purpose.

In this publication you will find detailed information about CSM implants.

Here https://www.vash-dentist.ru/implantatsiya/proizvoditeli/superline-koreyskogo-kachestva.html all the most important things about Superline implants.

German dental implants

Germany is also one of the most famous manufacturers of dental implants. Having started their activity mainly in the 80s, German implant manufacturers have established themselves with excellent product quality and successful developments, which subsequently contributed to the merger with American concerns. Today Germany is represented by SHUTZ, Xive, Ankylos, Impro, and other lesser-known systems. All of them are close to the top segment, have a good line of implants and orthopedic solutions. Precision and scrupulousness are valued all over the world, which is why German dental implants have many fans among specialists.

German-made dental implants cost an average of 30–35 thousand rubles, which puts them on par with most American-made implants. Ankylos will cost a little more (about 40 thousand) - a system whose characteristics are closest to the luxury class.

Line of German dental implants Zimmer

Project Description

The dental laboratory is an enterprise for the production of various dental prosthetic designs - zirconium, ceramic crowns, clasp, bridge dentures, acrylic plates and implants.

The company is focused on cooperation with dental clinics or private offices. To implement the idea, it is planned to rent a premises with an area of 100 m2 and bring it into compliance with SES requirements. The production of prostheses will be carried out using modern German equipment.

List of laboratory services:

- production of removable and non-removable crowns from various materials;

- production of zirconium and composite linings;

- production of whole and partial bridges;

- production of individual prostheses.

Korean dental implants

In the 90s, the field of medicine and dentistry became one of the priorities for the Korean economy, which allowed the country to become one of the leading suppliers of dental equipment. In the production of implants, Korea represents the budget category, and the most famous Korean dental implants are Osstem and Implantium. The advantages (besides the price) include a very wide range of models and good survival rate. They are quite popular on the Russian market, especially in the Far Eastern region of our country. However, some experts believe that these implants are not intended for all clinical cases and are inferior to top-end systems in terms of achieving an aesthetic result. Today, the price of Korean dental implants averages about 20 thousand rubles, which is quite good, considering their quite acceptable quality.

Line of Korean dental implants

Implants NDI Medical (“Rusimplant”)

These implants have quite an interesting history. Initially, production was based in Germany. When entering the Russian and CIS markets, several companies merged with NikoMedical. Thus, German technologies and Russian resources were combined together. Today, all products are manufactured under the NDI Medical brand, and production is still concentrated in Germany. The price for installing implants ranges from 15,000 rubles for standard systems to 35,000 rubles for the “Lux” system. The products of this company have a number of features that have a very positive effect on their quality.

- Reinforced Titanium Alloy Grade 4. This is a classic and very high quality alloy that is reinforced to the strength of the most modern Grade 5.

- Surface of Smart implants. This coating is a modification of the well-known SLA surface and is obtained by sandblasting and acid etching. The macro-rough coating minimizes the possibility of bacterial accumulation and also reduces the time of osseointegration (up to 2 months in normal bone tissue).

- Extensive range of implants. The company currently produces five systems of different shapes and sizes for specific clinical situations. The model range is indeed quite wide, but NDI Medical, by and large, copies the design solutions of famous manufacturers.

- Not a bad orthopedic briefcase. This includes both standard and angled abutments for esthetic prosthetics, as well as multi-unit abutments for the All-on-4 concept.

Israeli dental implants

Together with Korean implants, Israel occupies an economy class niche, and the Alpha Bio and MIS systems (especially the first) are very popular in Russia. This is not only due to price: the manufacturer invests significant sums in promoting its products. Israeli dental implants are very reliable, are well suited for restoring the chewing part of teeth and do not require the clinician to have any outstanding skills. In general, reviews of Israeli dental implants are very positive. However, there are also weak points.

Many clinicians note the lack of wide possibilities in prosthetics, which inevitably affects aesthetics.

The price of Israeli dental implants is very attractive. For 17–20 thousand, clinics offer installation of a titanium root, and turnkey implantation will cost an average of 40 thousand rubles. If lesser-known Israeli systems are used, the price will be even lower.

Israeli dental implant MIS

Business Investments

Investments at the start include spending on:

- registration – 4000;

- formation of authorized capital – 10,000;

- renovation of the premises - 500,000;

- purchase of equipment – 2,336,000;

- purchase of raw materials – 50,000;

- website creation and promotion – 50,000;

- advertising campaign – 50,000.

Total: 3,000,000 rubles.

The bulk of the investment (78 % ) will be spent on equipment for the production of dentures. The second largest expense item is funds for the arrangement and repair of premises.

Russian dental implants

Dental implants are also produced in Russia, although few people know about it. For example, there are IRIS implants - an improved LIKO-M system, which appeared more than 20 years ago. IRIS is produced in Italy using Russian technology and has an international certificate of ISO 9001-2000.

The abbreviation IRIS stands for Innovative Russian Dental Implant System Liko-M. Implants are made from pure GRADE-4 titanium. Premium implants from Nobel Biocare, Astra Tech, Straumann are made from the same material.

The first implant was developed in 1995 by a team of scientists led by Doctor of Medical Sciences, Professor, Corresponding Member of the Russian Academy of Sciences Sergei Yuryevich Ivanov. The scientific basis of the Iris Liko-M system is 55 dissertations defended under his leadership.

Search for premises

To implement a business idea, you will need a rented premises with a separate entrance of 100 m2. The location of the facility is not of fundamental importance, since the manufactured products will be delivered to local dental clinics by couriers.

Requirements for production premises:

- Availability of a working supply and exhaust ventilation system.

- The presence of 7 separate rooms - the main one, where the assembly and storage of prostheses, plaster, polishing, soldering, foundry, polymerization, and utility rooms are carried out.

- Finishing walls and floors with materials that are easy to clean.

- Ceiling height – 3–3.5 m.

- Connection to water supply, sewerage, central heating system.

- Good lighting.

Attention! The production premises must comply with the requirements of SES and SanPIN.

How important is the manufacturer of a dental implant?

In conclusion, I would like to note that the brand certainly influences the cost of the implant, but it is naive to think that you are paying such large sums just for the name. Top implants offer the broadest possible options for both the patient and the clinician. None of these systems compromise between functionality and aesthetics: it allows you to solve the patient's problem and give him a beautiful smile, even in difficult clinical situations in which a budget system could not perform in the same way. However, economy class systems today are of very high quality and, for certain indications, can become a worthy alternative to more expensive analogues.

Content:

- Brand Description

- Indications

- Contraindications

- Advantages and disadvantages

- Models

- Implantation and service life

Replenishing missing teeth with implants has become the norm today. But implantation using European models is an extremely expensive procedure: not everyone can afford it. Domestic Konmet implants have become an excellent alternative to well-known Swiss brands, which have gained popularity due to technical characteristics worthy of foreign analogues, and at a price that compares favorably with them.

What to look for when choosing, besides budget

Any implantation system will comply with the characteristics declared by the manufacturer only if professionally installed. Therefore, it is important to approach the choice of a clinic and specialists with a high degree of responsibility to whom you entrust expensive dental restoration. If possible, it is better to give preference to implantation centers that work with implants of the same brand, whose specialists actively cooperate with the manufacturer and undergo qualification and training courses at its production base.