2013

To fix the prosthesis in the mouth, preventing it from moving, clasps are used in orthopedics.

With their help, pressure is redistributed during the act of chewing. At the same time, they cover the dental unit only 2/3 of its circumference, creating support and ensuring retention of the prosthesis.

Background of creation

In 1949 of the last century, American researchers (dentists, mathematicians and metallurgists) developed and implemented the Ney system. The principle of the new system was the use of clasps made by casting, which load the tooth only in the axial direction.

This technique has become a breakthrough in prosthetics, since when installing clasps there is no need to wear crowns, and its use is possible for any condition of the teeth.

In addition, the newest procedure turned out to be safe for the patient, since it does not cause traumatic damage to the surface enamel.

Requirements for the location of clasps

To successfully install clasps you must:

- So that the tooth itself is very stable. If the doctor identifies pathological mobility, he will attempt to block it in order to ultimately obtain a stable system. If the patient’s teeth have inflammatory processes at the apex of the tooth, then before installing the support they must be sealed.

- So that the teeth have the correct anatomical shape. Teeth with a rather low crown along the cone, with an incorrect ratio of the length of the root and the clinical crown itself, as well as teeth with an exposed neck, are not suitable for installing clasps. The listed symptoms are relative. They can be eliminated and you can safely proceed to installing clasps.

- So that the supporting tooth has the correct relationship with the antagonist. Relationships can be very close. In this case, even a very small pad, which is placed in the fissure itself, greatly disrupts the bite. In such a situation, a completely different tooth is chosen to install the supporting element. Another solution is to install a protective crown on the initially selected abutment tooth.

Classification

Taking into account the selected material, clasps can be made of metal, plastic, or combined materials (a combination of metal and plastic). Ney's system is performed in 5 variations.

Anchor system

This variety is widespread due to its design features. Due to the rigid support anchor, the mobility of the structure is eliminated, which prevents displacement of the prosthesis.

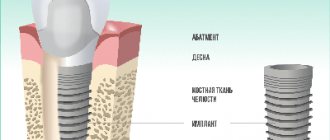

It consists of an occlusal pad of two arms and a body. The design features of the anchor system are as follows:

- The placement of the onlay is perpendicular to the axis of the dental unit. In this case, an inclination of the coronal part is allowed.

- The body of the structure is located on the distal surface at approximately 90⁰ to the occlusal pad.

- The shoulders extend from the body of the structure along the occlusal surface (to the boundary line) at an angle of 45⁰.

The structure of the anchor arm is divided into three parts:

- The supporting part provides rigidity to the structure, which leads to stabilization of the prosthesis.

- The elasticity of the product is given by the retaining part located in the gum area. It fixes the orthopedic structure.

- The intermediate part ensures semi-rigidity of the clasp connection.

The anchor system allows you to cope with defects in cases where the oral and vestibular dental surfaces are divided into approximately two equal parts.

The limitation in use is situations when a high location of the boundary line is fixed. Due to the lack of springy properties, the orthopedic design element is installed only between the chewing surface and the dividing line.

At the same time, the coverage of the tooth should be within ¼ - ½ of its perimeter, without penetrating into the cervical area.

The disadvantages of products of the first type include situations that limit the scope of application. They are also:

- when installing the structure, the shoulder covers a significant part of the dental unit, which is why food debris can accumulate under its surface;

- limited scope of application (installation only on molars is allowed).

The secret of the popularity of Yamahachi artificial teeth among specialists and patients.

Come here if you are interested in the pros and cons of palateless dentures.

At this address https://www.vash-dentist.ru/protezirovanie/semnyie-p/zubnogo-deflex.html you will find the characteristics of Deflex dentures.

Roach system

The second type of Ney or Roach system has the second name of split clasps. This is due to a design feature (the presence of two T-shaped arms).

The product is also equipped with 1 occlusal pad. These products can be used on either one or both sides of the support unit. They are mainly used for clasp prosthetics.

The shoulder extending from the frame intersects with the neck of the tooth. To minimize damage and premature failure, the beginning of the shoulder is made using a large section.

To ensure that the structure has sufficient elasticity and strength, materials such as gold, platinum, chromium, and cobalt are used in manufacturing.

Roach clasps have their own characteristics (small contact of the shoulder with the surface of the tooth). This quality allows you to stabilize the prosthesis in the oral cavity. Practitioners recommend using them in tandem with rigid anchor systems.

The use of this type of design provides the following positive characteristics:

- the installation ensures good retention of the supporting teeth;

- have the best aesthetic indicator when compared with other designs;

- lack of contact with the surface of the teeth reduces the chance of developing carious cavities;

- can be used when the units are tilted or when they have a small height;

- relative simplicity when adjusting the retinal ending.

The disadvantages of type 2 systems include:

- the shoulders of the product do not allow the use of clasps in the case of strongly pronounced bony protrusions;

- the absence of a rigid part in the rod arm reduces the effectiveness of the product compared to the anchor system;

- not used in the smile area;

- If handled carelessly, the elements may be damaged.

Combined

Ney's type 3 system is called combined. It combines the rigidity of the anchor arm and the elasticity of the Roach system. Thanks to this combination, clasps can be used on premolars, molars and canines.

When used, the boundary line may be at different levels. In this design, the holding element is the shoulder of type 2 products (Roach). Based on the inclination of the tooth, it is placed in the vestibular or oral position.

The placement on the lingual side occurs if the clasp is intended to be installed on a tooth that is a support in the mandibular row. On the vestibular side, the same lock with a shoulder anchor system is used.

The situation is different when installing this element on a tooth in the maxillary row. In such a situation, a shoulder of type 2 products (Roach) is installed on the side of the cheek, and an amnker system is placed on the side of the palate.

It is important to know! In terms of its parameters, this type of design is practically not inferior to systems of types 1 and 2.

The main symptoms of an allergy to dentures and ways to solve the problem.

In this publication, we will consider contraindications to the installation of a partial removable laminar denture.

Here https://www.vash-dentist.ru/protezirovanie/semnyie-p/vidyi-klammerov.html everything about the types of clasps and their components.

Clasps 4 types

Single-arm structures are also called reverse-acting. They are used when the dividing line is located atypically. This occurs in the case of cervical or lingual inclination of premolars or canines, as well as in conical or low coronal teeth.

In orthopedic practice, single-arm clasps with distal and medial pads are used. The use of the latter helps prevent the base from shifting away from the alveolar process.

According to the classification, they are called rear-action clasps. Their installation most often occurs on the mandibular row (although they can be used on the upper jaw) on canines or premolars. A high boundary line is a contraindication to installing a type 4 structure.

Type 1 single-arm structures provide support through the use of an occlusal pad, which branches off from the arm (distal part). It is an intermediate section and provides semi-rigidity of the system.

The rigidity of the clasp connection is created on the shoulder area located on the oral side of the unit (it is encircled). The vestibular part serves as an elastic base , which allows for tight fixation of the prosthesis on the jaw.

A special feature of the product is the conical shape of the shoulder, which is maintained throughout its entire length, allowing you to maintain a sufficient level of elasticity.

The use of type 4 products with any type of onlay (distal or median) is possible only if the premolars are stable.

For minor mobility, it is best to use a design with a medial pad in combination with multi-link ones. This will ensure an even load.

Single shoulder ring

Products of type 5 have 3 options for use, on the upper or lower jaw and a clasp with one lining. This type of clasp connection is installed on molars.

In this case, it is allowed to tilt towards the oral side on the mandibular row. On the upper row, the design can be used if the tooth is tilted in the opposite (vestibular) direction.

The peculiarity of the clasp is that it consists of one or two occlusal pads, and an elongated arm that covers the surrounding dental unit. This attachment creates rigidity, strength and stability of the prosthesis.

Due to the large length of the ring clasp, the likelihood of its deformation increases. Therefore, the structure is strengthened by connecting the rod to the shoulder and the distal pad to the arch on the maxillary row.

The same sequence of connecting elements with the base on the mandibular row allows you to significantly increase the strength of the orthopedic product.

This type of construction has a complex structure, which is why food debris can accumulate under its surface. This can cause the development of caries or inflammatory diseases of the gum tissue.

Need to know! Practitioners initially place crowns on single molars, after which clasps are installed. This ensures proper hygienic care.

The video presents the principle of creating clasps.

Types of clasps

Let us next consider several common types of clasps.

Material

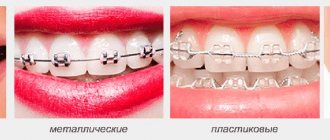

Fixing elements for removable dentures can be made of various materials:

- Metal. Most often, products are made of medical steel, chromium-cobalt or gold-platinum alloy. These materials are highly durable and ensure maximum service life of the entire structure.

- Plastic. They are used in butterfly prostheses and nylon elastic structures. Designed to perform a holding function, since they are prone to deformation and breakage under chewing loads.

- Combined. Contains both metal and plastic elements. Most often, this type is used in orthopedic pads.

Tooth Coverage

The coverage of teeth by clasps can vary significantly in different designs. Thus, there are dentures with single-arm, double-arm, T-shaped, multi-link, double and reversible methods of covering the supporting teeth.

Each method of placement on the dental surface has both advantages and disadvantages, so the choice of a specific fixation method depends on the specific clinical situation.

Form

Depending on the cross-sectional shape, round, semicircular and ribbon clasps are distinguished.

Round clamps are the easiest to manufacture. They ensure effective fastening of the prosthesis if placed correctly and a sufficient number of support units are used.

Semicircular clasps are used when covering abutment teeth with metal crowns. They are usually made from a spring alloy.

Tape hooks are used less and less due to the difficulty of fitting them to the tooth surface.

Connection to base

There are three options for connecting the clasp to the prosthetic structure:

- Rigid fixation involves a fixed attachment of the hook to the base, as a result of which the chewing load is transferred to the teeth through the clasp.

- The spring connection is ensured using a spring extension. The pressure of the prosthesis is only partially transferred to the teeth.

- The articular connection is made using a hinge. In this case, there is completely no pressure on the supporting teeth, and the load is placed on the mucous membrane of the alveolar ridge.

Functions

According to the variety of functions they perform, clasps can be supporting, holding, or combined.

This is interesting: Caring for dentures - the subtleties of polishing and the tools used

Support products are attached to the canines and molars using hooks and participate in the process of redistributing the chewing load.

Retaining elements are designed to secure the prosthesis to the elements of the jaw arch when performing vertical movements.

In combined support-retaining clasps, various types of load are redistributed between periodontal tissues and the prosthetic bed.

conclusions

Despite the fact that Ney clasps were developed in the middle of the last century, their use is still relevant today.

The simplicity of the design ensures high practicality, wear resistance, and, importantly, after installation a high degree of aesthetic value is noted.

In addition, to minimize the occurrence of breakage, areas located closer to the base are made thicker and more durable, and distant sections tend to gradually thin out, taking on the shape of the oral cavity.

If you find an error, please select a piece of text and press Ctrl+Enter.

Tags: removable dentures

Did you like the article? stay tuned

Previous article

Aquasplint is an innovative method of treating and diagnosing TMJ abnormalities

Next article

How to effectively and quickly remove plaque?

How clasps are made

The hook with which the denture is fixed can be made only using existing theoretical knowledge and concepts of a particular specialty. To make the right clasp, you need to know what types of prostheses will be attached with its help. The manufacturing technology of any clasps has the same sequence of actions. Here it is very important only to correctly follow the stages of the entire process and select the right material.

The clasp is always bent with pliers. Any dental technician has them in his arsenal. You can also use round nose pliers and pliers to make a clasp, with which you can make only three bends.

To obtain the clasp arm itself, designed to cover the tooth, one end of the cast wire is bent. The next bend is made using round nose pliers. Using these tools, the body of the clasp is also formed.

Requirements for making a shoulder

- Firstly, the design of the shoulder itself must be made so that it can cover the tooth from the cervical or labial side. It should be located behind the convexity line or otherwise between the gum and the equator.

- The shoulder should not create pressure on the supporting tooth itself, that is, it should be passive.

- Regardless of whether the shoulder is flat or round, it should touch the entire surface of the tooth as much as possible. If the fit is carried out only at one point, this means that increased pressure will be created on the tooth and, over time, the enamel will be erased.

- After the main stages of shaping, the shoulder must be rounded and polished. This is necessary in order to prevent possible injury to the mucous membranes.

- The shoulder must be elastic. The best in this case are wire clasps, not so good - cast ones. However, cast ones more accurately replicate the features of the tooth relief.

Execution of the contact process

In order to fix the created clasp shape, you must use round nose pliers. It is best to bend to the ridge using pliers. Next, the resulting process is crushed on an anvil and notches are made on it so that it is more firmly attached to the base.

Only single-arm clasps are made using the described method. In the case of double-arm execution, the sequence of actions is the same, only two elements are involved in the manufacturing technology.

Manufacturing

There are several ways to make clasps. Plastic products are usually made by injection molding. First, the product is shaped using wax, then it is replaced with the base material. Stamped models are produced by stamping from metal alloys. Bent systems are made using tongs. The technician may also use pliers or needle nose pliers. With their help, the master gives the wire the desired shape.

Stages of making a clasp using the bent method:

- using pliers, one end of the wire is bent to create the shoulder of the product;

- a second bend of the wire is performed to form the body;

- the wire is bent a third time to form an appendage.

Basic principles of the Ney system

The clasps are manufactured using injection molding technology, which ensures a variable cross-section of elements (horn-shaped arms), precision, compactness and ergonomic design.

The arms that support the rods and other parts of the clasps have an increased cross-section in areas of greatest stress.

The variety of types of Ney designs makes it possible to satisfactorily solve the problem of attaching clasp dentures in various clinical situations.

Other types of fasteners

Bonneville flip design

Bonneville is a variation of Acker, but the shoulders are directed in opposite directions. The retainer is designed for a continuous row of teeth. The design reliably fixes the prosthesis and creates high-quality support for it. The fastener also masks the gaps located between the teeth.

Other advantages of the Bonneville flip-over design:

- prevents food from getting stuck in areas considered difficult to reach;

- prevents the occurrence of certain pathologies of the oral cavity;

- prevents the development of an inflammatory process in the gums.

Swenson

Swenson - a clasp used on fangs

The product creates a reasonable load on the supporting teeth, which is especially important when they are mobile

Disadvantage: Some space between molar and premolar is required to secure the anterior shoulder of the product.

Double single arm design

There are two types of products:

- For the upper jaw - used from the side of the entire dentition and for two molars located next to each other.

- For the lower jaw - used in the presence of two converging molars.

Jackson

Jackson is a reversible clasp. This is a type of support-retaining device. The design has two branches and two bodies, is made in the form of a loop, and is also made in two ways - bent and cast.

Video: denture with and without clasp.

Adams

Adams is a universal clasp. The design fits tightly to the support, which ensures high-quality fixation of the prosthesis.

Dentoalveolar clasp

Dentoalveolar clasp - plastic is used for production. Used on front teeth in aesthetically significant areas of the oral cavity. For reliability, the plastic is reinforced with wire. This increases the strength of the structure, but negatively affects the quality of the material.

Flaws:

- the lip is slightly deformed, protruding forward, which negatively affects the appearance;

- cannot be used for supports with a low crown;

- records are not reused;

- cannot be used for the alveolar process.

The reliability of fixation of the prosthesis and the aesthetics of the smile depend on the clasp. For this reason, it is recommended to approach the choice of design with all responsibility.

Manufacturing Basics

Clasps are made by technologists who focus on the prosthesis that will be installed on the patient. The manufacturing technology goes through the following sequence of actions:

- the clasp is essentially a hook that secures the prosthesis, so it is given the desired shape using specialized forceps, round nose pliers or pliers;

- first, a shoulder is formed that covers the dental crown;

- then the body itself is formed.

Dental technicians make the necessary bends to form clasps quickly and accurately, in just a few bends.

Features of the production of the shoulder and contact process

The desired shape of the clasp is formed using round nose pliers. The contact process and the shoulder are formed as separate elements using different tools.

The contact process is first formed with pliers and then flattened on an anvil. This procedure is necessary to apply special notches that promote tight bonding of the process to the base.

A number of rules apply to the manufacture of a shoulder:

- the shoulder must have a sufficient level of elasticity, which is more typical of wire elements than cast ones;

- the shoulder is designed in such a way that its parts lie between the gum and the equator;

- when fixed to an abutment tooth, the material should not cause discomfort;

- the element must adhere to the tooth surface at all points of contact in order to prevent excessive pressure and thinning of the enamel;

- After rounding the shoulder, it must be thoroughly polished to avoid possible trauma to the mucous systems.

The video shows the manufacturing process of Jackson clasps.