Features of the material

Unlike structurally similar polyamides, Deflex exhibits high levels of functional elasticity, allowing it to be classified as a semi-rigid thermoplastic. This provides the material with a number of advantages, since prosthetic structures made on its basis are superior to acrylic models in many respects.

In particular, the polyamide in question is resistant to temperature changes, which eliminates hardening and softening of the structure when eating hot or cold food. Minimal porosity and high texture density guarantee strength and durability of the structure, capable of withstanding significant mechanical loads. Deflex reacts minimally with liquids, preventing the formation of plaque, does not absorb odors and is impervious to aggressive coloring pigments. Due to the structural features of the material, the thickness of the finished prosthesis is almost half that of analogues made of nylon or acrylic, which ensures ease and comfort of wearing, and also eliminates the possibility of speech defects developing during the adaptation period.

Research shows that dentures made from Deflex polyamide allow you to correctly distribute the chewing load on the dentition, preventing the mixing of supporting units, and maintaining the original position even under significant external influence. In addition, the material does not provoke an allergic reaction, which, combined with a visually invisible, colorless structure, makes it the optimal choice for prosthetics.

A little about the manufacturer

Dental Import Export Company Dentimex was founded in the Netherlands in 1938. The company began its activities with the production of removable products made from acrylic materials.

A gradual increase in the product range, expansion of production capacity and the conquest of new markets led to the reorganization of the manufacturer and its focus on the production of high-quality innovative premium materials for the manufacture of dental structures.

Currently, Vertex-Dental is known in more than 75 countries around the world. It is engaged in the production and distribution of various components for the manufacture of structures:

- hot and cold curing plastics;

- insulating liquids;

- polishing materials.

Particularly popular in orthopedic dentistry is the monomer-free plastic Vertex Thermosens, which makes it possible to produce systems for patients with increased sensitivity and susceptibility to allergic reactions.

Areas of application and contraindications

The range of uses of polyamides is quite extensive. Thus, the factors determining the need for installation of prostheses made of Deflex material include:

- Detection of defects and anomalies, including partial edentia;

- Complete absence of dental elements on one of the jaws;

- The patient is allergic to metal compounds.

Due to the reliable fixation of supporting elements, polyamide prostheses are recommended in the treatment of patients with periodontal disease and periodontitis, which is due to the absence of prerequisites for increasing the mobility of the remaining units. In addition, the models under consideration are used in situations where enamel preparation is excluded for medical reasons.

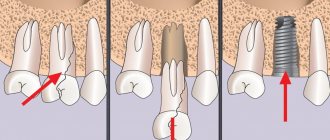

The strength and rigidity of dentures allows them to be used by people whose work or sports activities involve intense impact on the dentition. It is almost impossible to break the structure or get injured due to its displacement. In addition, in situations where the patient is prohibited from implantation, the polyamide design becomes a worthy alternative.

The minimum number of contraindications for use is another advantage of Deflex. The list of restrictions on the installation of prostheses comes down to the following factors:

- Identification of pathologies of bone tissue structure;

- Diagnosis of mental disorders;

- Presence of cancer;

- Acute or chronic inflammatory processes.

In addition, removable prosthetics are not recommended for patients undergoing radiation therapy, or those suffering from depression, alcohol or drug addiction.

Price issue

In large clinics, the cost of restoring teeth with a complete Deflex denture varies from 40 to 70 thousand rubles. The final price depends on the following points:

- the amount of treatment performed before installation;

- method of fastening the structure;

- specialist qualification;

- status and pricing policy of the clinic.

Partial models will naturally be 15-25 thousand rubles cheaper. A design that will replace only 1-3 teeth costs no more than 15 thousand rubles.

Advantages and disadvantages

The positive aspects of using the structures in question, noted by both dentists and patients, include:

- Correct distribution of mechanical load on the maxillary region;

- Resistance to temperature fluctuations;

- Reliability and density of fixation, including retention;

- Minimal adaptation period and absence of discomfort;

- Easy care and cleaning of the prosthetic system;

- Immunity to odors, dyes and other negative factors;

- Preservation of taste perception and speech structure.

Thus, Deflex technology is superior to removable dentures made of acrylic or nylon in most respects. However, there are also disadvantages, including:

- Manufacturing and installation costs. Prostheses made of polyamide are more expensive than their analogues, which, however, is compensated by their operational and aesthetic characteristics;

- Insufficient brand awareness. Due to the fact that Deflex is just entering the Russian market, name recognition and assessment of advantages are still inferior to those of competitors;

Impossibility of repair. The polyamide structure eliminates the possibility of gluing or re-welding the structure.

Installation steps

The manufacture and installation of any model of removable systems is faster and easier than non-removable products. The entire process of restoring missing teeth can be divided into 2 stages: clinical and laboratory.

The clinical stage includes the following activities:

- Study of anamnesis . The doctor interviews the patient about his state of health, living conditions and occupation, studies his medical record in detail, and also finds out whether he has had experience with prosthetics and how comfortable the device was.

- Instrumental examination of the oral cavity, which determines the condition of the mucous membrane, remaining dental units, chewing muscles, and the quality of oral hygiene.

The sensitivity of teeth is assessed, the symptoms of dental pathologies are identified and the degree of their severity is determined. - Hardware examination of the dental system. Before prosthetics, CT (computed tomography), orthopantomogram, radiovisiography, MRI are used

- MRI (magnetic resonance imaging). The results are necessary to determine the limitations or indications for prosthetics, the choice of technique for restoring the dentition and the type of structure.

Thanks to a complete examination of the dental system, a specialist can identify hidden dental pathologies, obtain information about the quality, density and volume of the jaw bone, the condition of the alveoli, dental roots, periodontal tissues and the temporal joint. - Preparing the oral cavity . Hygienic cleaning, removal of remaining roots that cannot be restored and impacted dental elements, and treatment of identified pathologies (inflammation, caries, etc.) are required.

- Selecting a removable device model. Taking into account the number of remaining teeth, the condition of the oral cavity, and the location of the defect, the orthopedic dentist selects a design model.

- Receiving an impression. Using silicone or alginate mass, an impression of both jaw arches is made.

After the impression arrives at the laboratory, the laboratory stage of prosthetics begins. The entire creation process takes place in the following sequence:

- The impression technician casts models of both jaws (entirely or only certain areas), from which the prosthetic product will later be made.

- The specimens are secured so that the position corresponds to the patient's centric occlusion. To avoid making mistakes, an occlusal roller is made, which is sent to the dentist to determine the patient’s occlusion.

- The model is fixed on the articulator. In this position, a model of the future prosthesis is cast from plaster. The cushion is removed and artificial teeth are placed in its place.

- The sample is sent for the first fitting , during which the correct selection of the shade of artificial teeth to real ones and the accuracy of closure of the jaw arches are tested.

- Fit. After checking, the model is returned to the laboratory, where the technician, taking into account all the comments, forms the final version of the design.

The finished product is tried on again for the patient. It should fit perfectly in all respects. If deficiencies are found, the design must be adjusted.

Watch the video to see how the Deflex prosthesis is made.

Reviews

Polyamide material Vertex, intended for the manufacture of removable dentures of the maxillary rows, is gaining increasing popularity both among dental technicians and among patients.

This is explained by the high performance characteristics of the finished product, as well as its similarity to the natural elements of the dentition.

Share information about the advantages and disadvantages of Vertex artificial teeth in the comments section of the article.

If you find an error, please select a piece of text and press Ctrl+Enter.

Tags dentures Vertex removable dentures

Did you like the article? stay tuned

Previous article

What are the most effective injections into the gums for periodontal disease?

Next article

Provocateurs of alveolar bleeding and ways to combat complications

Possible breakdowns

Damage to the integrity of Vertex products is quite rare, however, dentists identify the following situations in which product repair may be required:

- chipping or loss of an artificial tooth is eliminated in a dental laboratory by installing a new element of the row;

- if the product adheres poorly to soft tissues, adjustment of the base may be required;

- Elimination of a broken lock is carried out by replacing it with a new one;

- When cracks or breaks in the base appear, it is repaired or a new structure is made.

Dentists pay attention that repairs should only be carried out by specialized specialists. Independent actions can cause even more damage to the structure.

Who are flexible prostheses indicated for?

- They are most often used to replace partially missing teeth. To install them, you do not have to grind down adjacent teeth, and for many dental patients this circumstance is a significant advantage.

- Due to their light weight, they are recommended for prosthetics for patients with loose teeth due to periodontal disease and with particularly sensitive tooth enamel, which is not damaged by nylon clasps.

- Hypoallergenic nylon dentures are appreciated by people who suffer from an allergic reaction to acrylic and have learned the “delights” of denture stomatitis.

But, like any other artificial structure, lower and upper dentures also have certain disadvantages that make them impossible to use.

Sticking effect

When making the base part, special attention is paid to the area where the gums come into contact with the cheek and lip. Thin and slightly elongated edges of the prosthesis completely cover these areas. This helps create a sort of circular valve that prevents air from leaking under the artificial gum. Advantages of this approach:

- Tight fit. Precisely manufactured adhesive dentures seem to stick to the mucous membrane.

- Aesthetics of the restored dentition. A smile looks attractive and natural.

- Comfortable use. The prosthesis sits firmly on the gums, without injuring either them or the tongue or the inner surfaces of the cheeks.

- Efficiency. You can even chew quite hard food with such teeth, without the denture moving.

Removable teeth based on an adhesive effect hold up much better than previous generation designs. In most cases, there is no need to additionally use adhesive agents, even on the lower jaw.