In addition to the plant in Israel, the company has production plants in France and Germany. The abbreviation MIS itself stands for Medical Implant System. Behind such a simple name lies a completely successful project. By the time of its twentieth anniversary, MIS managed to reach a high production level and produces more than one and a half million implants per year. This is a very good indicator, taking into account the fact that most market leaders began their activity back in the 60s and 70s of the last century. Why did “Mis” dental implants become such a popular system in a short time? The answer is simple: they have an excellent price-quality ratio plus a fairly wide range of products for various clinical cases.

MIS implants - catalog of solutions for all cases

The official MIS website says that MIS Liment implants and orthopedic components are produced at a factory in Israel. Each implant produced by "Mis" (Israel) undergoes sandblasting and acid etching, which makes its surface similar in structure to natural bone tissue. Many MIS implants have a combined shape and an unusual thread pitch with special spiral-shaped tubules in the apical zone (at the tip). This concept is designed to provide primary stability during installation and optimal osseointegration.

MIS C1

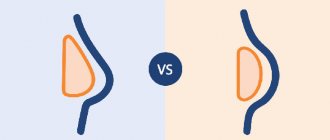

The standard MIS implant is conical with a hexagonal connection and is designed to closely resemble the root of a natural tooth. Typically used for classic two-stage implantation, however, the manufacturer states that the C1 line can also be used with immediate loading (when a dental implant and temporary crown are installed during one visit).

MIS V3

One of the company's advanced developments. The implants of this series have a triangular coronal shape, which helps ensure the stability of the artificial root during installation and correctly distribute the pressure on the bone tissue. The design also allows for the preservation of the volume of soft tissue above the platform, which is why the installation of the MIS V3 implant often occurs for aesthetic restorations in the smile area. The diameter of the V3 series implants ranges from 3.30 to 5 millimeters, and the length - from 8 to 16 millimeters.

MIS SEVEN

These are self-tapping implants with double threads, the thickness of which increases from the tip to the neck. A universal system that is suitable for different types of bone, and is also installed during bone grafting. The shortest implants in this series are 6 millimeters long.

MIS M4

This series is a screw implant of a combined cylindrical-conical shape. Used for both two-stage and one-stage implantation techniques.

MIS UNO

A one-piece design that is designed specifically to replace missing incisors of the lower and upper jaws. Implants from this line are often used as a support for bridges.

MIS Link

This is a line of MIS orthodontic implants, which are not used in classical implantation, but are designed to perform a supporting function during orthodontic treatment.

Histology (Paulo G. Coelho, DDS, PhD New York University College of Dentistry):

The gist of the clinical study (published in the Journal of Oral and Maxillofacial Surgery) below is that osseointegration between tight bone contact and loose contact will occur in different ways. With tight contact, there is high primary stability of the implant, but as a result, larger areas are subject to necrotic “die-back,” reconstruction, and a resulting decrease in primary (mechanical) stability until new bone formation begins. In the case of “free contact”, the primary stability of the implant is low, but as a result of slight compression of the bone, the number of areas susceptible to necrosis and remodeling is minimized, while the growth of new bone tissue begins in this case much faster, which leads to a faster onset of the secondary phase. (biological) stability of the implant.

In what clinical situations would MIS be suitable?

As the manufacturer of MIS implants indicates on its official website, implant surgeons can use them for:

- dental defects,

- complete absence of teeth,

- impossibility of using a removable prosthesis.

MIS implants are suitable for restoring teeth in the upper and lower jaw, and both classical implantation is possible in two stages (installation of an artificial root, and then, after its engraftment, loading with prostheses), and one-stage - after installing the implant, a temporary prosthesis is immediately fixed on it . To perform one-stage implantation using MIS, it is necessary to achieve good primary stability and acceptable occlusion.

Narrow implants (with a diameter of 3.3 mm) can only be used in those areas of the jaws where there is a partial absence of anterior and (or) lateral incisors, i.e. narrow implants are designed to restore the smile area.

Abutments

MIS abutments represent a reliable link between the denture and the implant itself. The abutment is finally installed after successful completion of the process of osseointegration and implant healing.

The types of abutments in the MIS series include the following:

- narrow orthopedic working platform;

- classic orthopedic platform;

- wide platform;

- orthopedic parts for multi-component composite abutments.

Multi-component abutments are used to carry out work with removable structures. The impression is taken using special transfers and similar installations of a multi-component abutment.

Orthopedic briefcase. Crowns for MIS implants

Modern implant companies must also have a wide range of abutments to provide decent prosthetics in a wide variety of clinical cases. The MIS company works quite productively in this direction and has a very wide selection of abutments with both cement and screw fixation. The range includes standard, spherical, as well as temporary abutments for attaching crowns to MIS implants during healing. Depending on the diameter of the implant itself, three abutment platforms of different widths are used.

What is the advantage compared to other systems?

If it is necessary to restore only one missing tooth, this remedy is very effective, for example, compared to a traditional bridge installation. First of all, this is explained by the fact that a standard bridge can only be attached to previously ground healthy teeth. At the same time, a process of bone loss occurs in the space under the bridge, as a result of which the patient faces a violation of aesthetics and the need for treatment of the supporting teeth, up to their complete removal and replacement of the bridge with a new one.

In the case of MIS implantation, only the missing tooth is restored, without the need to damage nearby teeth. In addition, the crown located on the device is designed to last longer than a conventional bridge. And with a well-performed operation, it is almost impossible to distinguish such an implant from a real tooth.

Once installed, implants can also become a reliable support and an effective alternative to removable and clasp dentures. They help maintain bone volume and protect adjacent teeth.

In general, compared to other types of prosthetics, this approach gives remarkable results, both from the functional and aesthetic sides, since it allows you to maintain the resulting type of restoration for a long time. This is made possible by using high-strength materials to produce an implant crown that is designed to last for decades.

Reviews from specialists about MIS implants

Many specialists from clinics where MIS implants are installed in Moscow call them the best budget system for dental implantation, especially since even an economy class clinic that does not have great financial resources can buy MIS implants. This status, of course, cannot be considered official, but the company is interested in doctors around the world giving preference to its implants and using them in their clinical practice. Good survival rate (exceeding 98%), a wide choice of prosthetics and ease of use are the main advantages of MIS for clinicians. In general, reviews of Mis implants from dentists are positive. However, there are doctors who are skeptical about this manufacturer, as well as about budget systems in general, since such implants do not allow achieving ideal aesthetics and are not designed to work in complex clinical cases.

Be that as it may, even though MIS is not a pioneer in the industry and a developer of advanced solutions, it rightfully occupies its place in the market. In addition, the high quality indicators of MIS are confirmed by a number of certificates. In particular, an independent study by POSEIDO, which examined implants from the most famous manufacturers, confirmed that the Mis implant (Israel) has one of the cleanest and most reliable surfaces.

MIS components

The main components of a typical long form MIS (Management Information System) are:

- People - people who use the information system

- Data - data that is recorded by the information system

- Business procedures are the procedures used to record, store and analyze data.

- Hardware refers to servers, workstations, networking equipment, printers, etc.

- Software are programs used to process data. These include programs such as spreadsheets, database software, etc.

Key advantages of MIS implants (Israel):

- good quality/price ratio;

- a good selection of “Mis” dental implants and related orthopedic structures;

- relatively short healing period: the MIS implant (Israel) takes 8 to 10 weeks on average, which is a very decent indicator for an economy class system;

- 5 year warranty on installed structure.

How much do MIS implants cost?

The price of MIS implants is approximately on the same level as Alpha Bio and Korean implants. In some clinics this system will cost a little more, but in general the cost variation is insignificant. In Moscow, the price of MIS dental implants (Israel) averages 17,000 - 20,000 rubles, which is almost two times less than treatment with implants from top manufacturers. Prosthetics with a metal-ceramic crown will cost approximately 40,000 rubles. At the same time, you should not think that you are overpaying only for the brand and that there are no fundamental differences between luxury and economy class implants at all. The brand, of course, greatly influences the cost of the implant, but it is naive to believe that you are paying such large sums just for the name. Top systems offer enormous possibilities for both the patient and the clinician, and also allow achieving ideal aesthetics even in difficult cases.

Final cutter

Standard sizes of final cutters for SEVEN implants

When using the final cutter, one should take into account its structure and geometric features, and as a consequence, the fact that the implant bed is lengthened (during its final formation) by the size of the apex of the final cutter. This must be taken into account during surgical planning. Below are the dimensions of the apexes of the final cutters based on the diameters of the implants.

* Recommended force when using the final cutter: 200 - 400 rpm.

* Shown in the video: the implant driver, as well as the form of external and internal packaging of the SEVEN implant are no longer used. They have been modified and improved. See section - SEVEN implant packaging

Surgical kit for implant placement SEVEN